High-Precision CNC Machining – ALEDJO DOO

ALEDJO DOO specializes in CNC machining of individual and small series parts, delivering exceptional quality, reliability, and precision at every stage of production. Our parts are used across Europe, and our long-standing experience combined with continuous investment in innovation enables us to tackle even the most demanding projects – with the same dedication to every client.

CNC Milling

A precise and reliable metal processing method, ideal for creating complex shapes with outstanding quality and accuracy.

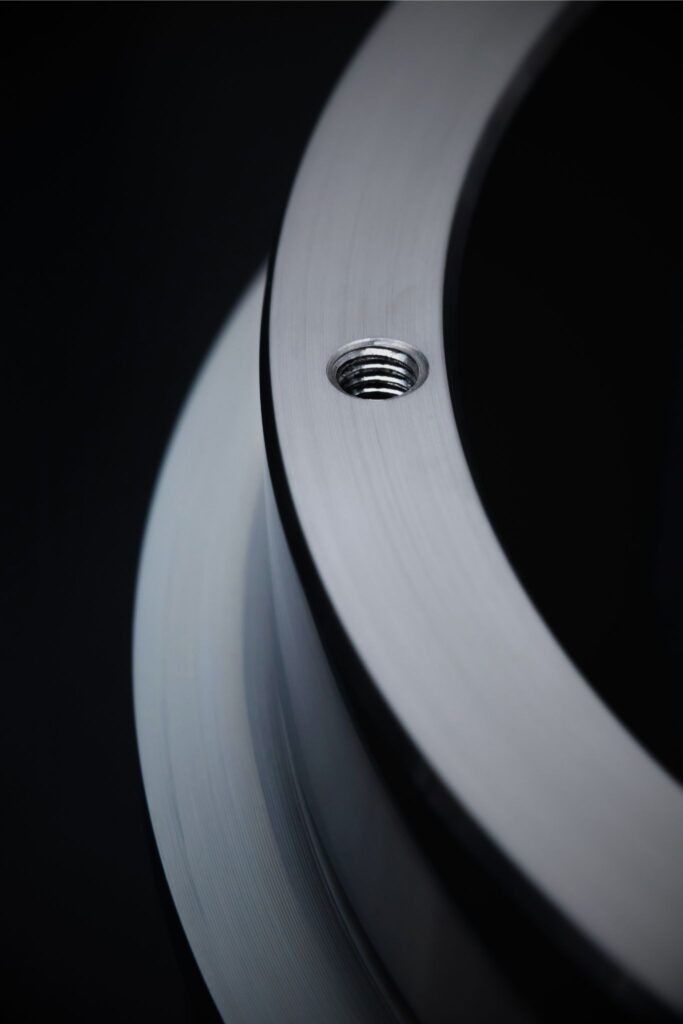

CNC Turning

An efficient technique where the rotating workpiece is shaped to meet your requirements – perfect for producing cylindrical and conical parts.

Design and Development

We offer personalized solutions from concept to finished product, with a professional approach that ensures optimal functionality and quality.

ALEDJO DOO – About the company

ALEDJO DOO is a company specialized in high-precision CNC machining of individual and small series parts. Since 1967, we have continuously invested in the modernization of our machine park and the professional development of our team, ensuring quality, reliability, and innovation in every project.

Certified to ISO 9001:2015, our processes meet the highest international standards, while our tailored solutions are designed to meet the specific needs of each client. Today, due to ongoing investments in modernization and innovation, we operate a modern machine park with over 20 CNC milling and turning machines.

Every client is important

Each client represents a unique opportunity for mutual success. We offer a personalized approach, flexibility, and expertise in every collaboration, because we believe that every idea deserves attention and a custom solution.

Quality and speed

We continuously invest in modernization – upgrading our machine park and adopting advanced software tools, enabling precise and fast production.

Skilled workforce

We invest in the development of our employees, ensuring our team stays up to date with the latest technologies and is always ready to meet market demands.

Standards

We are certified according to ISO 9001:2015, demonstrating our commitment to the highest standards of quality, precision, and safety.

Material stock

Thanks to reliable suppliers, we ensure fast procurement of raw materials – plastics, alloyed and unalloyed steels, stainless steel, aluminum, copper, brass, and other metals.

Environmentally responsible business

By optimizing our processes, we reduce waste and resource consumption. We use eco-friendly and recyclable packaging, contributing to environmental protection.

Proven experience

Years of collaboration with numerous domestic and international partners confirm our commitment. Our projects and the growth of our clients speak to the trust we build with each collaboration.

The trust we build across Europe

From traditional metalworking to modern CNC manufacturing

We began our work back in 1967 as a small craft workshop, providing blacksmithing and locksmith services. Through decades of dedicated work, we transformed in 1992 into a mechanical and forging workshop. With further development, in 2006 we became a metal processing company, and since 2016, building on our extensive prior experience, we have focused on modern CNC technologies. Over the years, we have positioned ourselves as a reliable partner on both domestic and international markets, continuously improving our processes and building a strong reputation in the industry.

Od zanatskih početaka do savremene CNC proizvodnje

Započeli smo svoj rad davne 1967. godine kao mala zanatska radionica, pružajući kovačke i bravarske usluge. Kroz decenije posvećenog rada, transformisali smo se – 1992. godine prerastajući u mašinsko-kovačku radionicu, dok smo 2006. godine postali savremeno metaloprerađivačko preduzeće sa fokusom

na CNC tehnologiju. Danas, ALEDJO predstavlja simbol inovacija i preciznosti u CNC proizvodnji. Tokom godina, pozicionirali smo se kao pouzdan partner na domaćem i međunarodnom tržištu, kontinuirano unapređujući svoje procese i gradeći snažan ugled u industriji.

Započeli smo svoj rad davne 1967. godine kao mala zanatska radionica, pružajući kovačke i bravarske usluge. Kroz decenije posvećenog rada, transformisali smo se – 1992. godine prerastajući u mašinsko-kovačku radionicu, dok smo 2006. godine postali savremeno metaloprerađivačko preduzeće sa fokusom na CNC tehnologiju.

Danas, ALEDJO predstavlja simbol inovacija i preciznosti u CNC proizvodnji. Tokom godina, pozicionirali smo se kao pouzdan partner na domaćem i međunarodnom tržištu, kontinuirano unapređujući svoje procese i gradeći snažan ugled u industriji.

Danas, ALEDJO predstavlja simbol inovacija i preciznosti u CNC proizvodnji. Tokom godina, pozicionirali smo se kao pouzdan partner na domaćem i međunarodnom tržištu, kontinuirano unapređujući svoje procese i gradeći snažan ugled u industriji.

© 2025 ALEDJO DOO. All rights reserved